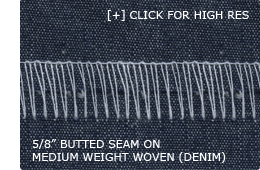

The Merrow 70-D3B-2 CNP is a chemically nickel plated version of Merrow's flagship 70-D3B-2. The nickel plating resists corrosion from liquids and dyes, making it the ideal machine for denims or other woven fabrics that are sewn when wet. The 70-D3B-2 CNP runs at 2250 RPM and sews a 5/8" stitch that is meant to be removed when the material has been completely processed.

The 70-D3B-2 operates like any standard sewing machine, and can be table or rail mounted. It is powered by a standard sewing machine motor, but for exceptionally hazardous environments should be paired with Merrow's pneumatic motor to eliminate the chance of fire from electrical sparking.

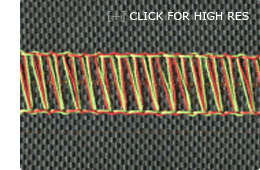

The Merrow Butted Seam for denim consists of a flat 5/8" stitch that joins the material end-to-end. The Merrow Butted Seam is a temporary stitch that is specifically designed for the continuous processing industry - it is made to be removable, yet is strong and flexible when applied.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Denim/Wovens

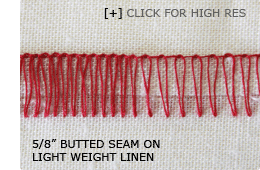

The Merrow 70-Y3B-2 sews a single thread butted seam on material that is being joined end-to-end. The machine is designed to double the stitch count at material selvages to mitigate folding backwards of the material during processing. The 70-Y3B-2 is fitted with an actuator lever that can be pressed while sewing to multiply the stitch count on demand. The stitch multiplier can be adjusted to regulate the amount of

stitches per inch in order to accommodate different cloth weights and structures. The actuating lever is located at the front of the machine where it can be easily accessed whenever and wherever the operator needs to increase the stitch count.

The Merrow Butted Seam for linen is a flat, single thread 5/8" stitch that joins piece goods end-to-end. The stitch lies exceptionally flat to allow for subsequent printing, coating, or pressing without the need for stopping at each seam.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Linen/Wovens

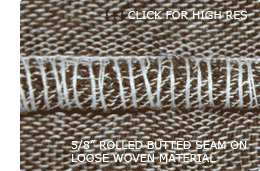

With superior fabric handling the 72 Class machines have become a favorite for Knit goods and a variety of non-woven processes. The 72-D3B-2 R Series ROLLS THE FABRIC as it sews creating a tough butted seam for loose knit or woven materials. The machine is especially useful when joining low count material end-to-end and is the perfect alternative for materials that cannot be joined using a traditional butt seam.

It is designed with a special feed system to handle difficult fabrics which incorporates six rows of feed dogs, forward mounted cutters, and an oversized presser foot and work plate. In combination with the rolling mechanism, this configuration allows the 72-D3B-2 R to roll material while wrapping the thread around it, creating a seam that will not separate.

The rolled butted seam wraps the two ends of joined material to prevent the seam from separating. It is the most effective way to join low count material end-to-end.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Low Count Material

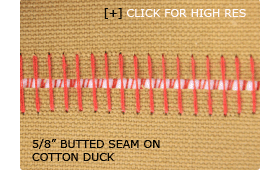

The 70-D3B-2 is Merrow's flagship Butted Seam sewing machine. It is constructed of high quality parts and materials, ensuring a lifespan that lasts decades without a degradation in performance. The 70-D3B-2 is built to be reliable and durable and to operate without interrupting the textile finishing process. The 70-D3B-2 can be configured in any

number of ways to accommodate all processes, applications, and materials, yet it runs like any standard sewing machine and can be mounted to a table or railway. Because of its performance, durability and predictability, the Merrow 70-D3B-2 is the industry standard sewing machine for joining materials end-to-end.

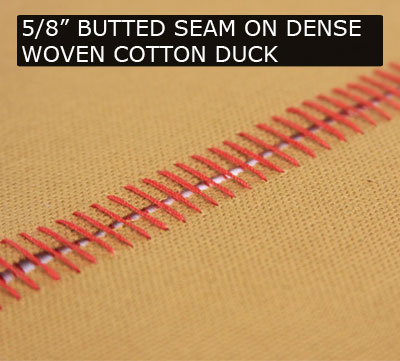

Merrow's 5/8" Butted Seam is used to sew cotton duck and dense woven cloth. The width of the stitch prevents the seam from unraveling the cloth and the low profile makes the seam nearly invisible to processing machinery.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Wovens

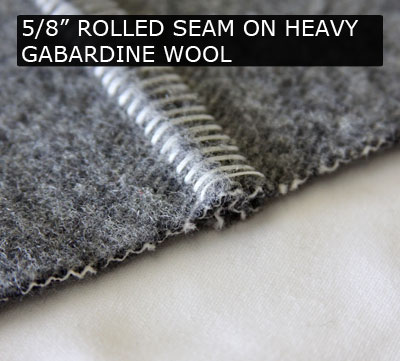

With superior fabric handling the 72 Class machines have become a favorite for Knit goods and a variety of non-woven processes. The 72-D3B-2 R Series ROLLS THE FABRIC as it sews creating a tough butted seam for loose knit or woven materials. The machine is especially useful when joining low count material end-to-end and is the perfect alternative for materials that cannot be joined using a traditional butt seam.

It is designed with a special feed system to handle difficult fabrics which incorporates six rows of feed dogs, forward mounted cutters, and an oversized presser foot and work plate. In combination with the rolling mechanism, this configuration allows the 72-D3B-2 R to roll material while wrapping the thread around it, creating a seam that will not separate.

The rolled butted seam wraps the two ends of joined material to prevent the seam from separating. It is the most secure way to join low material end-to-end.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Gabardine

The Merrow 70-D3B-2 CNP is a chemically nickel plated version of Merrow's flagship 70-D3B-2. The nickel plating resists corrosion from liquids and dyes, making it the ideal machine for denims or other woven fabrics that are sewn when wet. The 70-D3B-2 CNP runs at 2250 RPM and sews a 5/8" stitch that is meant to be removed when the material has been completely processed.

The 70-D3B-2 operates like any standard sewing machine, and can be table or rail mounted. It is powered by a standard sewing machine motor, but for exceptionally hazardous environments should be paired with Merrow's pneumatic motor to eliminate the chance of fire from electrical sparking.

The Merrow Butted Seam for laminated fabric is a flat 5/8" stitch that joins the material end-to-end. The stitch is extremely flat and is designed to undergo subsequent finishing processes such as laminating, dyeing, or mercerizing.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Treated Wovens/Fabrics

The Merrow 70-D3B-2 LS sews a flat 5/8" stitch that locks the seam in place, yet gives with the material being sewn. Initially designed to fill the need for a stitch that was flat enough and secure enough to withstand napping processes, the 70-D3B-2 LS is also used to sew materials that need to flex without separating at the seam. For this reason

it is becoming increasingly popular in construction applications that use permeable fabrics or materials that are layered between uneven or porous surfaces. The 70-D3B-2 LS excels at joining woven fabrics and geotextiles, yet is versatile enough to sew knits and non-wovens.

Merrow's Locked Butted Seam is a flat, permanent stitch that is strong yet malleable. It was created for applications that involve heavy processing or for material that must be joined permanently while still allowing for flex.

- SPEED: 2250 RPM

- STITCH WIDTH: 5/8"

- MATERIAL: Woven Geotextiles